Creating a stable, effective, and patient-friendly topical formulation requires both scientific precision and regulatory awareness.

Formulation scientists must balance drug efficacy, skin compatibility, and manufacturability all while meeting strict regulatory guidelines set by agencies like the US FDA, EMA, and CDSCO.

At Topiox Research Centre in Navi Mumbai, our experts follow a stepwise formulation approach that integrates pre-formulation assessment, design optimization, stability testing, and scale-up validation.

This ensures that every product developed whether a cream, gel, ointment, or lotion meets global pharmaceutical benchmarks for quality, safety, and performance.

Pre-Formulation Assessment: Building the Scientific Foundation

Pre-formulation is where success begins.

This phase determines how the active pharmaceutical ingredient (API) behaves under different conditions and ensures it can be safely and effectively delivered through the skin.

Key studies include:

- Physicochemical characterization: melting point, partition coefficient, pKa, hygroscopicity, and solubility profile.

- API-excipient compatibility: identifying potential interactions that could affect stability.

- pH and buffer range studies: ensuring the formulation’s pH remains within physiological limits (typically 4.5–7).

- Analytical method development: establishing LC, HPLC, or UV-based assays for API quantification.

A robust pre-formulation program minimizes future formulation failures and forms the scientific foundation for every subsequent step.

Formulation Design and Optimization

Once pre-formulation data confirms API compatibility, scientists move to design the delivery system balancing functionality, aesthetics, and performance.

Key Formulation Parameters

- Choice of Base:

Creams (oil-in-water), ointments (water-in-oil), gels (hydroalcoholic or carbomer-based), or lotions (emulsion systems). - Excipients Selection:

Stabilizers, surfactants, viscosity modifiers, penetration enhancers, humectants, and preservatives. - API Incorporation Technique:

Whether dissolved, dispersed, or emulsified, depending on solubility. - Optimization Studies:

Performed using Design of Experiments (DoE) to balance rheological properties (viscosity, yield stress) and drug release profiles.

Formulation trials are conducted at multiple pH levels and temperatures to determine the optimal matrix for long-term stability.

Process Development and Scale-up Feasibility

Once a lab-scale prototype meets all quality specifications, the next step is process optimization.

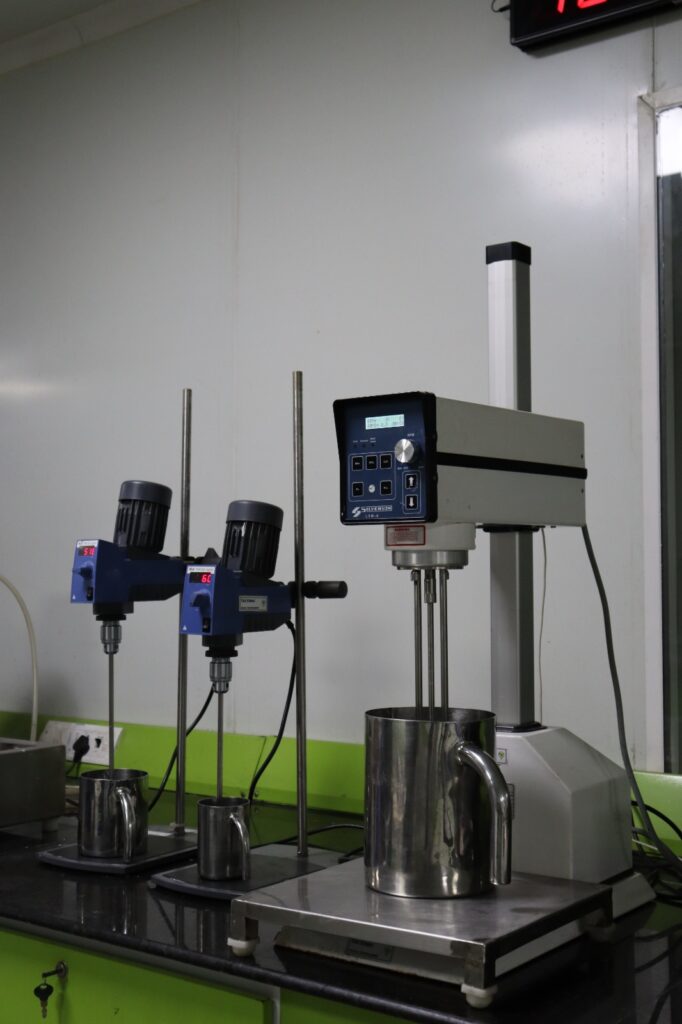

At this stage, mixing time, homogenization speed, and temperature profiles are studied and recorded to ensure batch reproducibility.

Scale-up feasibility is tested in pilot batches that replicate GMP manufacturing conditions using equipment such as:

- Homogenizers and planetary mixers

- Emulsification units

- Inline viscometers and temperature probes

This ensures the product’s critical quality attributes (CQAs) remain consistent, whether produced at 1 kg or 100 kg scale.

Stability and Performance Testing

A well-designed formulation must demonstrate physical, chemical, and microbiological stability throughout its shelf life.

Stability studies are conducted under ICH Q1A (R2) guidelines:

| Study Type | Duration | Storage Conditions |

| Accelerated | 6 months | 40°C ± 2°C / 75% RH ± 5% |

| Long-Term | 12–24 months | 25°C ± 2°C / 60% RH ± 5% |

| Intermediate | 6 months | 30°C ± 2°C / 65% RH ± 5% |

Performance Evaluation

- In-vitro Release Testing (IVRT): Determines how efficiently the API diffuses from the formulation.

- In-vitro Permeation Testing (IVPT): Measures skin absorption characteristics.

- Rheology and Texture Analysis: Ensures batch-to-batch uniformity and consumer acceptability.

At Topiox Research, all performance tests are conducted using validated analytical methods such as Franz Diffusion Cells, HPLC, LC-MS/MS, and FTIR spectroscopy.

Analytical Method Validation

Method validation is not just a regulatory formality it’s the cornerstone of reliable data.

Analytical techniques must meet ICH Q2 (R2) standards for:

- Specificity

- Linearity

- Accuracy

- Precision

- Detection & quantification limits

Validated methods ensure that formulation results are scientifically defensible and accepted by agencies worldwide.

Scale-Up, Manufacturing Readiness, and Documentation

Once formulation and analytical methods are validated, pilot-scale batches are manufactured.

Critical process parameters are defined and recorded as Master Formula Records (MFR) and Batch Manufacturing Records (BMR).

Regulatory Documentation Includes:

- Detailed formulation composition

- Manufacturing flowchart and control strategy

- Analytical validation reports

- Stability data summary

- IVRT and IVPT study results

At this stage, your product is ready for ANDA, NDA, or CTD dossier submission.

Common Pitfalls in Formulation Development

Even experienced developers face challenges.

Common mistakes include:

- Inadequate pre-formulation: skipping compatibility studies leads to phase separation or API degradation.

- Poor excipient justification: choosing non-functional or incompatible ingredients.

- Late optimization: making critical changes after stability initiation.

- Ignoring microstructural analysis: missing Q3 equivalence parameters like droplet size or crystallinity.

Addressing these proactively ensures smoother regulatory reviews and consistent product performance.

Why Partner with a Specialized Research Centre

At Topiox Research Centre, formulation development is more than lab work; it’s a regulatory strategy.

Our team integrates pharmaceutical chemistry, analytical validation, and formulation engineering to accelerate drug development timelines.

Key Capabilities

- Custom excipient and polymer synthesis

- Q1/Q2/Q3 characterization

- IVRT and IVPT alignment

- Skin hydration and bioavailability studies

- Regulatory-ready documentation

Our facility in Navi Mumbai, India, supports clients across the US, EU, and Asia-Pacific regions with full data traceability and GLP-compliant systems.

Experience and Integrity: The Core of Our Scientific Practice

| Attribute | How Topiox Demonstrates It |

| Experience | Over a decade of formulation design and stability testing expertise |

| Expertise | Advanced analytical tools including LC-MS/MS, DSC, and rheometers |

| Authoritativeness | Work aligned with ICH Q1A(R2), USP <1724>, and FDA topical guidance |

| Trustworthiness | Transparent, reproducible documentation built on ALCOA+ principles |

Conclusion

Topical formulation development is a scientific journey one that blends creativity, precision, and regulatory insight.

Every step, from pre-formulation to validation, contributes to the product’s quality and therapeutic success.

At Topiox Research Centre, we help pharmaceutical companies navigate this journey with confidence from molecule to market.For an integrated overview of formulation, characterization, and testing, explore our

Topical Product Development: End-to-End Solutions for Pharma and R&D.

Faq's

Topical formulation development involves several stages: pre-formulation studies, excipient selection, prototype design, stability testing, in-vitro release/permeation evaluation (IVRT/IVPT), and scale-up. Each step ensures the product’s safety, stability, and therapeutic effectiveness before regulatory submission.

Pre-formulation studies determine the physical and chemical properties of the active ingredient. This step helps identify potential stability issues, compatibility with excipients, and suitable formulation types such as creams, gels, or ointments.

Excipients influence the formulation’s texture, spreadability, drug release, and absorption. Choosing the right emulsifiers, humectants, and penetration enhancers ensures consistent delivery and stability throughout the product’s shelf life.

Regulators often require Q1/Q2/Q3 characterization, IVRT and IVPT studies, and stability testing. These confirm formulation sameness, performance equivalence, and safety essential for ANDA or marketing authorization submissions.

Early optimization prevents rework during bioequivalence or stability studies. By identifying and resolving formulation issues early, companies can minimize failed batches, reduce development timelines, and strengthen regulatory confidence.